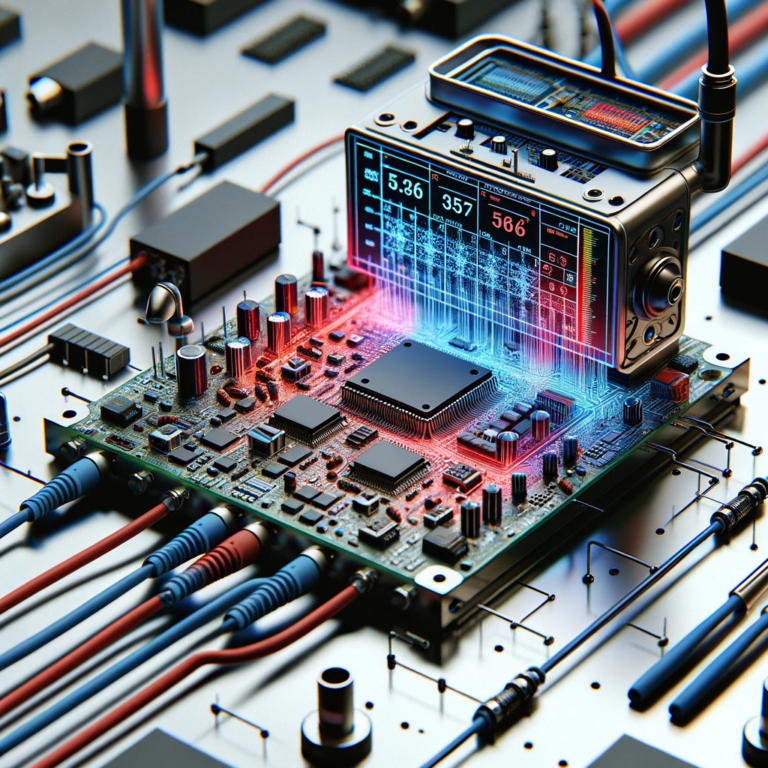

Unlocking Efficiency and Reliability: The Power of PCB Thermal Analysis Services

Understanding PCB Thermal Analysis

Critical Importance: Thermal management in electronics crucial for PCB efficiency and reliability.

Invaluable Insights: Thermal analysis services assess PCB thermal behavior.

Optimization Benefits: Enables design optimization, overheating prevention, and device lifespan extension.

The Need for PCB Thermal Analysis: Addressing Heat Challenges

Miniaturization Heat Issues: Smaller, powerful devices generate more heat, impacting performance and lifespan.

Hotspot Identification: Thermal analysis pinpoints potential hotspots and temperature distribution.

Proactive Solutions: Early analysis aids in addressing heat issues, component placement, and cooling strategies.

Performance & Reliability: Ensures optimal device performance and minimizes thermal failure risks.

Evaluating Thermal Design Parameters: Key Factor Analysis

Comprehensive Evaluation: Analysis covers thermal conductivity, heat dissipation, and junction temperatures.

Simulating Conditions: Assesses temperature impacts under various operating scenarios.

Design Phase Considerations: Influences material choice, trace widths, and heat sink implementation.

System Reliability: Aims for reduced thermal resistance and improved thermal performance.

Optimizing Cooling Solutions: Ensuring Effective Heat Dissipation

Critical Cooling Mechanisms: Essential to prevent PCB overheating.

Solution Effectiveness: Analysis evaluates heat sinks, fans, and thermal vias.

Simulation of Airflow: Helps determine suitable cooling strategies for specific designs.

Lifespan Extension: Reduces hotspots and enhances component longevity.

Mitigating Thermal Challenges in Advanced PCBs: Handling Complexity

Advanced PCB Challenges: HDI boards and multilayer designs present unique thermal issues.

Heat Dissipation in Complex Structures: Analysis assists in optimizing thermal vias and copper planes.

Reliability & Performance: Focuses on signal integrity and maximizing intricate design performance.

The Role of Simulation and Modeling: Advanced Analysis Techniques

Revolutionary Tools: CFD and FEA for accurate thermal predictions.

Strategic Fine-Tuning: Enhances thermal management strategies for better product reliability.

Efficient Design Process: Reduces iterations and accelerates market readiness.

Conclusion: The Impact of PCB Thermal Analysis Services

Empowering Engineers: Facilitates optimal thermal management in electronic devices.

Ensuring Device Integrity: Focuses on efficient heat dissipation and reliability.

Safe Operation: Maintains safe temperature ranges to prevent thermal failures.

Driving Innovation: Advanced simulation and modeling bolster industry innovation and success.